Global Container and Order Management

Accurate container and order visibility and control has long been the ultimate goal for manufacturers (OEMs) and lead logistics providers (LLPs), however the software solutions market has never really embraced or facilitated this goal, preferring to focus solely on individual segments or modes thereby further perpetuating the antiquated, silo’d approach to supply chain management.

This partly because container management can mean many things to many people as do container management software solutions. Whereas service providers may be interested in little more than the container itself and its cargo classification, the shipper of that cargo will be interested in far more detailed information about the cargo including shipment order information, purchase order, packaging media and SKU level information.

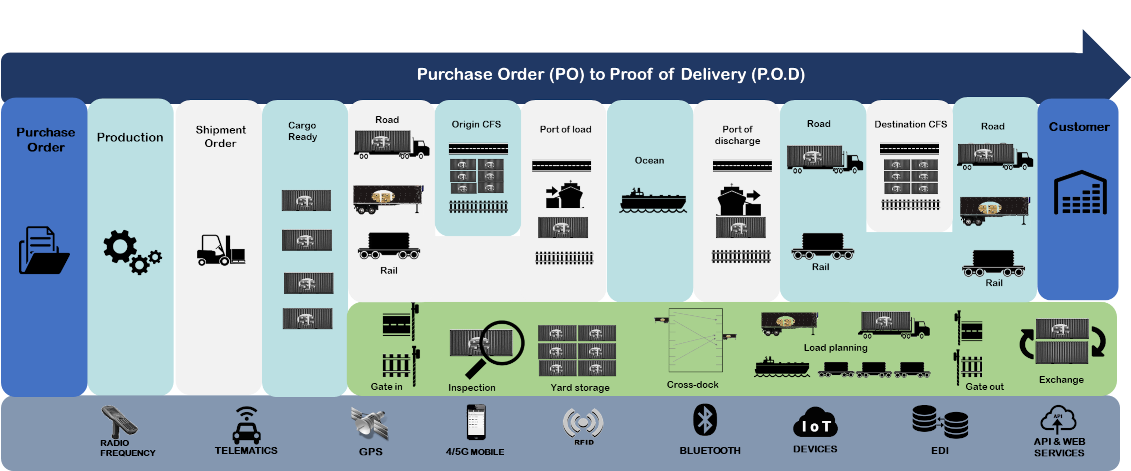

Knowing which SKUs are in which containers, which order lines they represent and which purchase order they reconcile against can be critical to the shipper. In addition, knowing where the container is destined, how it will be routed there and what are the latest ETAs at each point in the supply chain and ultimately its final ETA it critical. This is especially true if the cargo is feeding local manufacturing plant or fulfilling the needs of time critical or seasonal sales channels. Having visibility and control of all of this information seamlessly, end-to-end visibility within one solution, ProAct calls a ‘Control Tower’.

A true Control Tower technology brings many benefits, not least that it can project more accurately, down to SKU level the availability of product currently in the supply chain at its final destination. Knowing what product is in which containers at what points in the supply chain also makes it easier to re-prioritise individual containers and expedite critical SKUs. All of this relies on the solution capable of having a detailed understanding of the entire process flow, its decision logic, its dependencies, its service providers, its constraints and overall the routing options for a specific container. This in turn relies on a technology that is dynamic, configurable and flexible enough to project, predict and optimise a complex end-to-end, multi-modal supply chain based on all of this data.